“1-DAY POLYUREA-POLYASPARTIC” COATING SYSTEMS: THE GOOD, THE BAD & THE UGLY

Concrete coating systems have become crazy popular. And with the increase in popularity, new coating companies are popping up everywhere. Many of them are “1-day polyurea” system installers…because the idea of single-day installation is appealing to prospective customers.

The contractor uses fast-cure coatings to get the job done quickly within the promised 1-day duration. But as with most things in life, “fast” doesn’t always mean “good”. GarageFloorCoating.com, which has been installing concrete coatings since 1996, wrote an article in August 2020, illuminating the good, the bad and the ugly of these 1-day systems in an article titled Polyurea-Polyaspartic One-Day Systems: Do They Work.

Polyurea vs Polyaspartic

1-day system installers use products called “polyureas” or “polyaspartics”. These products possess fast cure rates and this is a critical requirement if you want to install a garage floor coating in a single day. Slower curing products would force an installation beyond one day.

But what’s a polyurea and polyaspartic? A polyurea is a coating with an extremely short cure time, yet durable enough to coat roofs, foundations, truck beds, and other surfaces. The problem with a “true” polyurea is that it cures so quickly (in seconds) that specialized equipment is required to apply it. A polyaspartic is similar to a polyurea (it’s an “aliphatic polyurea”)…it’s been chemically modified to cure slower. So a polyaspartic is just a modified, slower-curing polyurea. (Albeit, “slow” is a relative term, as a polyaspartic is still “fast-curing” relative to, say, an epoxy).

What Constitutes a 1-Day System?

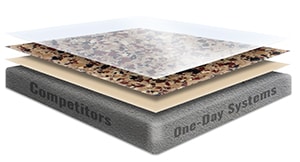

1-day systems typically consist of 3 layers: (i) a thin polyaspartic primer coat (or aliphatic polyurea…what ever you want to call it) applied direct-to-concrete, (ii) a full broadcast of thermoplastic flakes, and (iii) a single polyaspartic clear top coat. All three layers are applied in rather quick succession…they can be because of the quick cure rate of the polyaspartic used as the primer coat and clear top coat.

The Good, The Bad and the Ugly

A polyurea-polyaspartic’s “fast-but-not-too-fast” cure rate and its ability to provide extreme UV, chemical and impact resistance, make it an excellent choice for use in concrete coating systems. That’s good. But a polyaspartic has an “Achilles heel”; it’s not meant to be applied direct-to-concrete under high-moisture conditions. They’re excellent color coats and excellent clear top coats….but not so good as direct-to-concrete primers.

Concrete is porous and water permeates from the soil beneath, up through the concrete, in a process called moisture-vapor transmission (MVT). This creates hydrostatic pressures which build over time…this pressure pushes up against the coating and may cause blistering, bubbling or peeling. And the thin polyaspartic primer coat that “1-day” contractors apply simply isn’t sufficient to protect the floor against high hydrostatic pressures. That’s bad.

So what does a 1-day contractor do? They provide “cover” by adding a warranty exclusion in their contracts against “moisture-related issues”. So when your 1-day coating peels due to high hydrostatic pressure, the warranty exclusion gets invoked. That’s ugly.

A Proper Way to Apply Concrete Coatings

Experienced contractors won’t use a polyurea-polyaspartic direct-to-concrete. Instead, they apply a thick layer of a moisture-mitigating epoxy as the primer coat; the polyurea-polyaspartic is only used as the clear top coat (by the way, we apply 2 coats of clear polyaspartic, not one, to produce an even thicker and more resilient coating). But because the moisture-mitigating epoxy primer has a slower cure rate, at least, slower than a quick-cure polyurea-polyaspartic, the installation time may span up to 2 days…not 1. It’s a slower installation process, but the thick epoxy primer can withstand very high hydrostatic pressures…that is, there’s a lesser propensity to delaminate.

Why Apply a 1-Day Coating At All?

Ultra-thin, “1-day” coating systems use a polyaspartic (or aliphatic polyurea) direct-to-concrete. This may work under low concrete moisture conditions…but it’s like playing Russian roulette. Because of this higher propensity to delaminate, 1-day installers don’t fully warrant “moisture-related issues”. So why do they install 1-day coatings at all? Because 1-day applications require less labor and use less material (a thin primer and single topcoat). This makes for very profitable coating system installations.

Then There’s Us

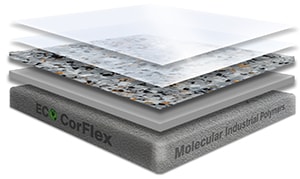

Conversely, Timeless Concrete Coatings only applies industrial-grade concrete flooring. We apply our proprietary, moisture-mitigating, 100%-solids epoxy as the primer (not a polyaspartic). It acts as a thick, moisture vapor barrier. We then broadcast your selected mica-stone infused chip blend in a full chip spread and top it all off with two coats…not one…of our clear 100%-solids polyaspartic.

The result is a 35+-mil thick, full-chip garage floor coating, guaranteed against all moisture-related conditions. We have an entire line of industrial-grade polyaspartic-polyurea coatings…and we use them in every garage…as clear tops coats. But never as direct-to-concrete primers!

Want one-of-a-kind, industrial-grade, full-chip mica-stone infused garage floor coatings with a real warranty? Call Timeless Concrete Coatings at (631) 696-8086 for your free estimate.