Long Island garages face it all—wet winters, salty coastal air, and fluctuating temperatures that stress concrete over time. At Timeless Concrete Coatings, we’ve heard every myth in the book about garage coatings. The truth? Garage floor epoxy is hands-down the best base coat for lasting performance.

Let’s clear up the confusion with a few facts.

Myth #1: “Polyaspartic works just as well for the base.”

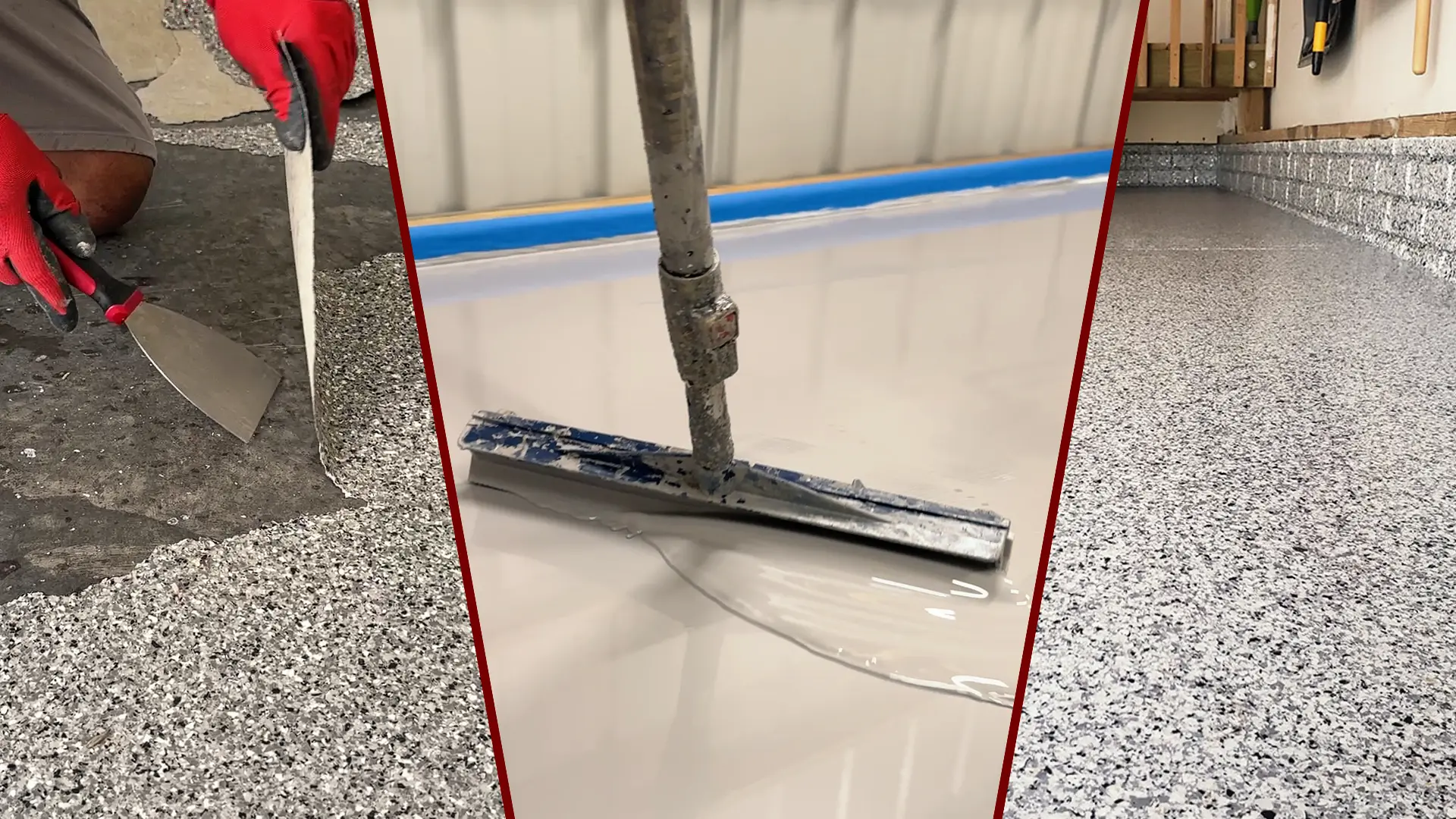

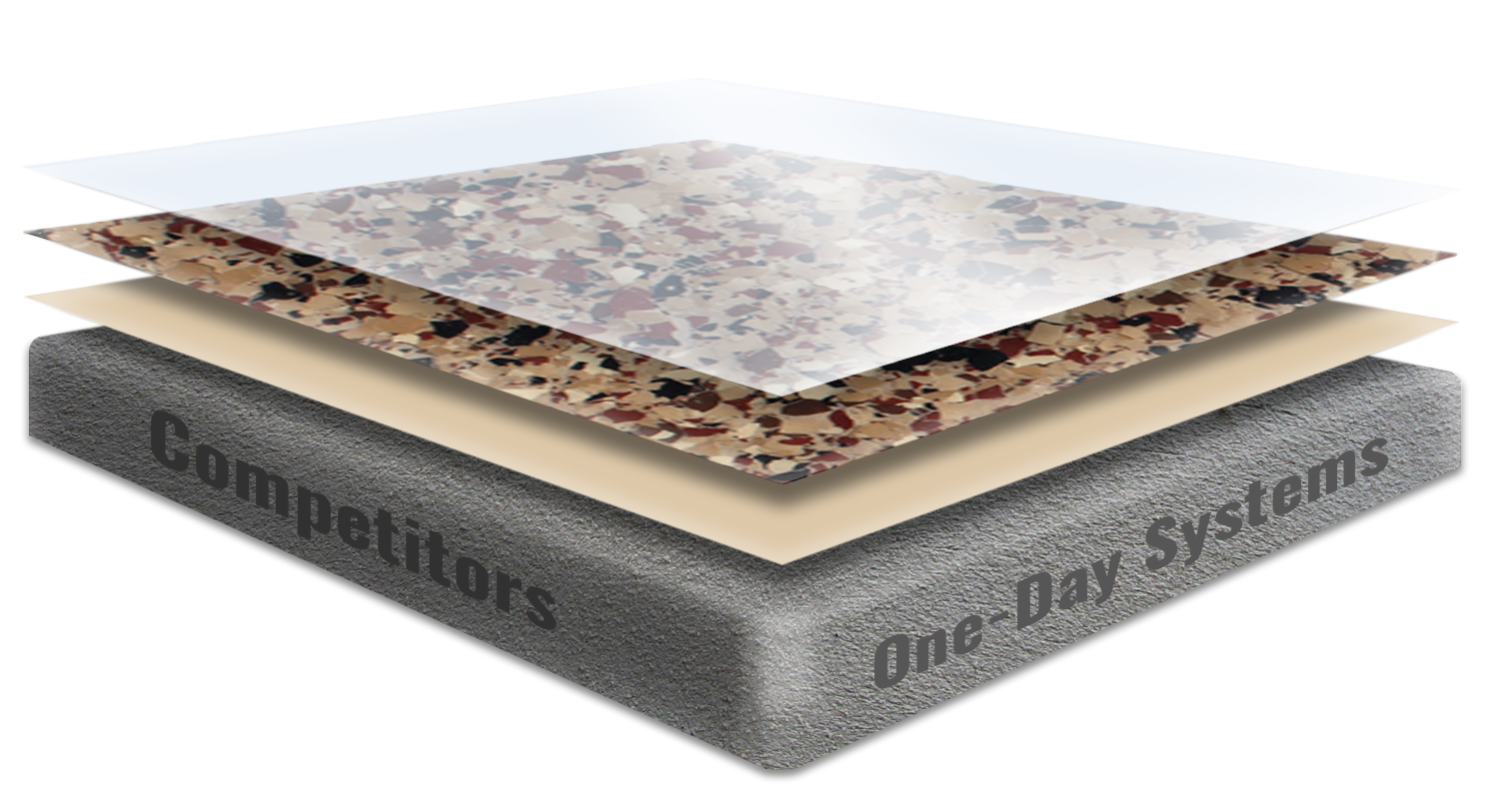

Fact: It doesn’t. A quick-curing polyurea or polyaspartic is a great topcoat, but these coatings have an Achilles heel. They make for lousy direct-to-concrete base coats. Why? Because the quick-cure coatings cure even quicker in the presence of moisture (or humidity in the air); so fast that they don’t deeply penetrate the concrete slab. This thin, weakly-bonded base coat can lead to early failures—especially in climates like Long Island’s. Conversely, garage floor epoxy cures slowly. We allow a full day of curing for deep penetration and bonding, ensuring the base coat is properly anchored to the concrete substrate.

Myth #2: “Moisture problems are rare in garage floors.”

Fact: Moisture is one of the biggest threats to floor coatings and the number one reason for coating failures. Whether it’s storm water, coastal humidity, or vapor rising from below the slab, moisture can lead to bubbling and delamination. The epoxy base coat provides a thick, moisture vapor barrier (MVB) that polyurea-polyaspartic base coats simply can’t match.

Myth #3: “If it looks good now, it’ll last.”

Fact: Looks are only surface-deep. Polyurea-polyaspartic base coats can only be applied thinly (due to the inherent chemistry of these coatings). The result is a thin, poorly-penetrating base coat that sits atop the concrete slab, leaving the entire coating system vulnerable to wear and separation. Garage floor epoxy can be installed thicker (it’s a high-build coating), giving your floor a sturdy foundation that stands up to heavy use.

Why Timeless Concrete Coatings Uses Epoxy

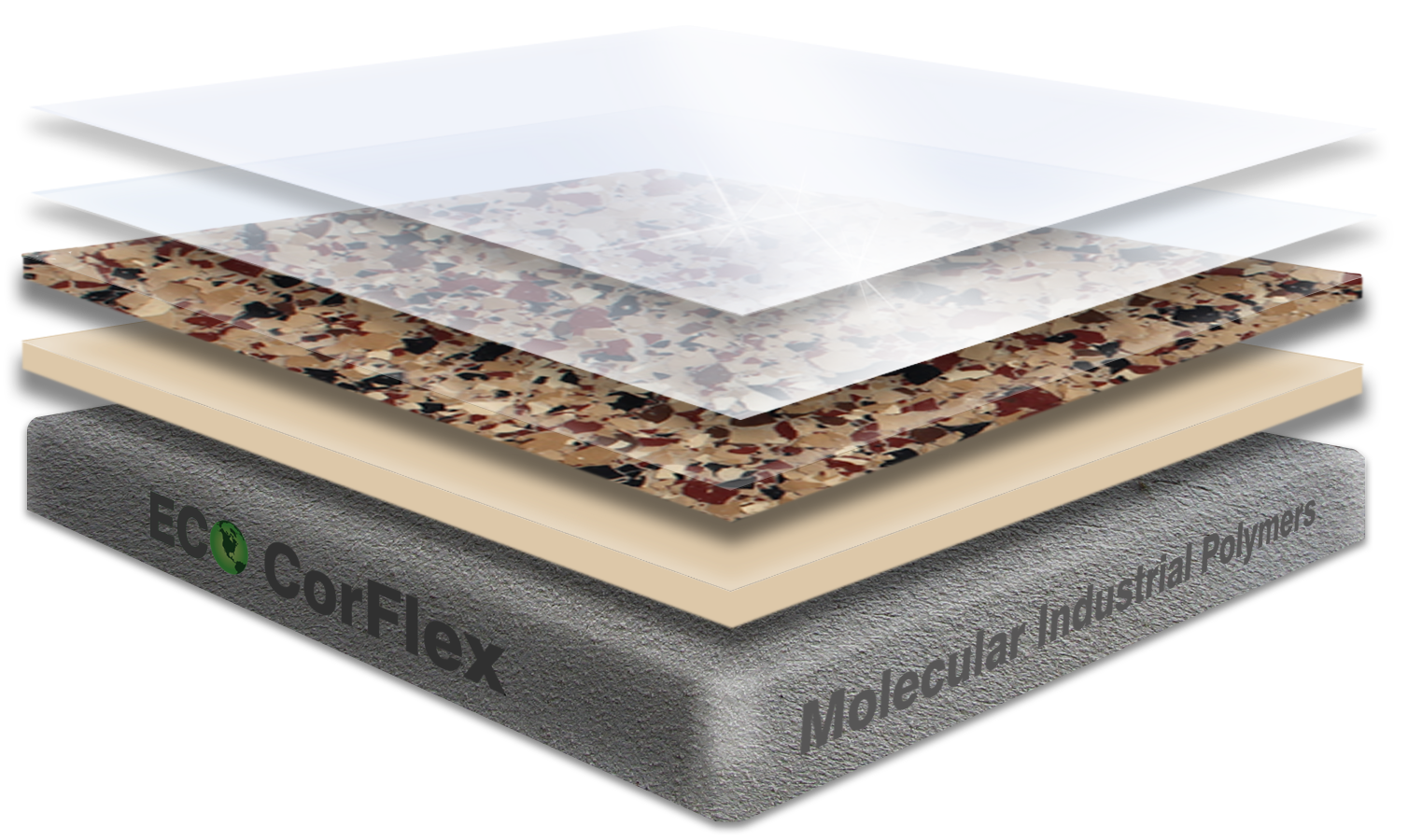

We install every floor using a proven 2-day system:

- A slow-curing, moisture-mitigating, 100%-solids epoxy base coat that acts as a moisture vapor barrier, providing unmatched adhesion and moisture control

- A full flake broadcast of your selected proprietary flake blend

- Two 100%-solids polyaspartic topcoats (not just one like the “1-day” coatings) that handle impacts, chemicals, stains and UV exposure

It’s not about speed—it’s about doing it right the first time.

Looking for garage flooring that’s built for Long Island’s unique conditions? Reach out to Timeless Concrete Coatings and discover the strength of a true garage floor epoxy system.